Continued from Part 1 on THE IMPORTANCE OF LOAD SECURING. Click here to read Part 1.

Tie-down Lashing

Tie-down lashing is the most common type of lashing for the transport of goods over the road. If the cargo is wide (if not wider than the truck tray), securing the load is only possible by vertical or slightly inclined tie-down lashing.

In the case of tie-down lashing, care must be taken to consider factors such as:

Note: Tie-down lashing only works if there is enough friction between the loading area and the load. For example, a steel load on a steel loading area does not offer enough friction which is why wooden supports or anti-slip mats should be used to increase friction.

Diagonal Lashing

For diagonal lashing, two angle plans (horizontal and vertical) should be considered and two angles defined. Diagonal lashing should be prioritised over tie-down lashing. This is because with diagonal lashing, the lashing equipment is not subject to pre-tensioning forces. The lashing equipment is only subjected to higher loads in the event of sudden braking, jerky start, or close cornering.

Are Lifting Points suitable for Lashing?

Lifting points are often installed for lashing purposes. However, lifting points are used primarily for lifting and therefore not marked with the permissible tensile force LC (Lashing Capacity - daN) but with their WLL (tonne). It is important to know that lashing points and lifting points are subject to different design factors. This is why you will find it easier to meet practical requirements with high-strength, tested, and field-proven RUD lashing points.

Weldable RUD lashing points are forged and available in blocks that can be easily welded. RUD lashing points with LC specification in daN can also be retrofitted to the vehicle carrier by certified welders. In addition to these weldable lashing points, RUD also offers an extensive range of boltable lashing points which can be used for load securing.

Tips for Skip Loaders - Optimum Load Securing with Angled Lashing

Load securing is always about the safety of people and the load. Also, having your load secure ensures that you do not run the risk of fines by the transport authorities. With RUD lashing products you be assured of safe transport of your cargo all the time.

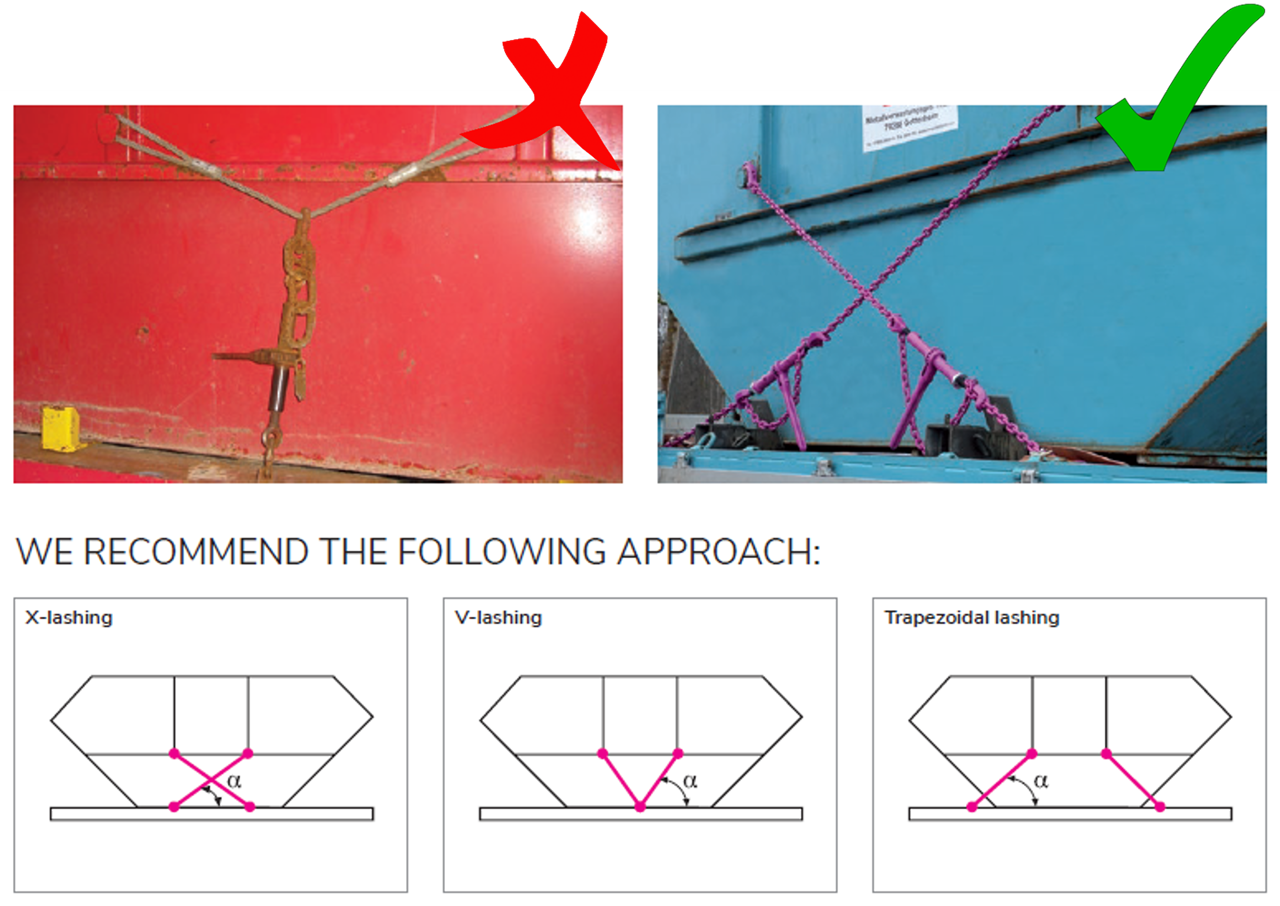

As shown in the pictures, tie-down lashing of trough containers is advisable in V, X, or trapezoidal angles with a fixed connection at the lashing point and the suspension pin. A Y lashing should be avoided because the load will not be adequately secured with this type of lashing.

Finally

If you are transporting heavy machines or cargo, it is important to plan load securing during the design phase components. This means, installing lashing points on both the load and the loading area.

Some of the points to note:

Visit us on Booth #380 (Plaza Level) to know more about our Lifting & Lashing Systems, Workshop Handling Solutions including Endurequip Portalift Hoists and Tyre Protection/Traction Chains.

Article copyright to RUD, this information is accurate at the time of publication and RUD Australia takes no responsibility for any errors inadvertent or otherwise.

If you want to know how the team at RUD can help you, please call 07 3809 1300 or fill out an enquiry form here.

Sources:

Fill out our easy form and we will be in touch soon with a tailor made quote.

I value the simplicity of design and ease of maintenance. Unlike other complicated electronic hoists on the market, the Portalift hoist are simple to service, with spare parts easy to get. This is important when you need your hoists to keep operating with minimum disruption. Portalift hoists are an asset to any workshop, heavy duty and reliable.